TRI Flow Technology

The most common problems encountered when performance camshafts are installed are the loss of bottom end torque, poor idle quality and computer problems.

The most common problems encountered when performance camshafts are installed are the loss of bottom end torque, poor idle quality and computer problems.

This phenomenon has been more and more prevalent with high-revving, multi-valve engines. When two valves open at the same time, there is twice as much room for the air to move through. Picture a vacuum hose that has a diameter of say 1". It could quite easily suck up marbles or small rocks. If that same vacuum was hooked up to a vacuum hose of say 5" diameters, what could it pick up? Maybe a feather, but the marbles and small rocks are totally out of the question. An engine works the same way!

When an engine is optimized for HIGH-RPM power, the LOW-RPM power will unfortunately have to be sacrificed... or will it?

What if someone could make a performance camshaft that could make better power at HIGH-RPM with a minimum low - rpm torque loss, without the use of a variable lift cam system?

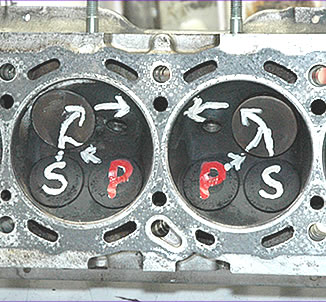

Colt Cams has managed to do just this for virtually ANY multi-valve engine. By staggering the opening times of the two intake lobes, we have created a swirl in the system. The principle behind this design is to open the intake valves progressively. Opening one valve first allows the fuel to travel across the chamber at a greater velocity due to the smaller venturi action, it then helps pull in the second charge at a faster rate.

This gives the equivalent to the secondaries opening up in a carburetor. In turn, with the larger cam, the engine has better vacuum at idle since there is less overlap, throttle response is greatly increased, and turbocharged vehicles have noticed less lag and faster spool up time. Geoff's theories on the "Tri-flow" have been proven time and time again, on many different engines. The testing has proven the theory, and now it is time to let the world see the results.